Delivering Hitachi Construction Machinery Reliability in the Massive Americas Market

- Nov 15, 2022

- 8 min read

Updated: May 18, 2023

CHAPTER 1

For Hitachi Construction Machinery, establishing an independent operation in the Americas required at least four things immediately: selling new and used machinery to dealers, making parts and services available, getting the parts remanufacturing system operational, and providing financing. Hitachi Construction Machinery Americas management had less than a year to get ready after the termination of its partnership with Deere was announced in August 2021.

A Game-Changer in the American Construction Machinery Market

In November 2021 the first excavators destined for sale in North America by Hitachi Construction Machinery Americas left the Tsuchiura Works, shipped as sea freight. After they crossed the Pacific they passed through the Panama Canal into the Atlantic to be offloaded at a port in Florida, then to eight dealers across North America. The orange excavators all sported the bold Hitachi logo.

Excavators are the origin of Hitachi Construction Machinery’s business and are highly competitive even in the international market. The first hydraulic excavator made with Japanese technology was developed and shipped in 1949 by a department of Hitachi, Ltd., well before Hitachi Construction Machinery was split off as an independent subsidiary in 1964. The firm’s product line-up grew to cover the complete range from compact to gigantic, delivering world-class safety, durability, and reliability. Hitachi Construction Machinery developed the global market, not just in the Americas, adding products including environment-friendly machinery and its ConSite service solution.

Now Hitachi Construction Machinery is gearing up to offer its excavators, drivers of the firm’s competitiveness, throughout all of the Americas, starting with the North American market.

“Hitachi Construction Machinery may well be a real game-changer for the Americas, because it could transform the conditions affecting competition in the market, and the whole situation. A lot of talented people recognize this and have come to Hitachi Construction Machinery Americas to help. Dealers and customers are really looking forward to it. After all, the whole brand is built on the highest technology and reliability. It’s a very exciting time.”

These words were spoken by Rob Orlowski, Director of Product Management and Engineering at Hitachi Construction Machinery Americas, who joined the company in May 2022. A veteran of the construction machinery industry, he has held management positions at several global manufacturers. Even with his extensive background in the industry, Orlowski was astonished at the technologies that come standard in Hitachi Construction Machinery’s excavators.

Rob Orlowski Director, Product Management & Engineering

Emphasizing the Latest Technology and Standard Equipment

One of those is TRIAS III, an energy-saving system for excavators that optimizes hydraulic fluid distribution in arms, booms, and slew ring platforms as needed, helping large excavators save fuel while operating at peak efficiency.

“It uses three pumps and three actuators to deliver incredible power while using less energy,” says Orlowski. “I watched it grab a stump in the bucket teeth and tug it without any trouble at all. Customers call it a ‘beast’ and a ‘monster’ when they see it in action.”

The firm has also released an evolved version of the ConSite service solution, dubbed ConSite Oil. Almost all construction machinery, not just excavators, is equipped with hydraulic pumps and the condition of the hydraulic oil directly affects machine performance. Prolonged use of degraded oil can lead to breakdowns and other machine trouble.

ConSite Oil uses artificial intelligence to constantly monitor oil conditions with sensors. If oil deterioration or other abnormalities are detected, the data is shared with the machine owner, the dealer, and Hitachi Construction Machinery itself, helping prevent major issues and increasing availability to reduce life-cycle costs.

Safer than Ever with “Aerial Angle”

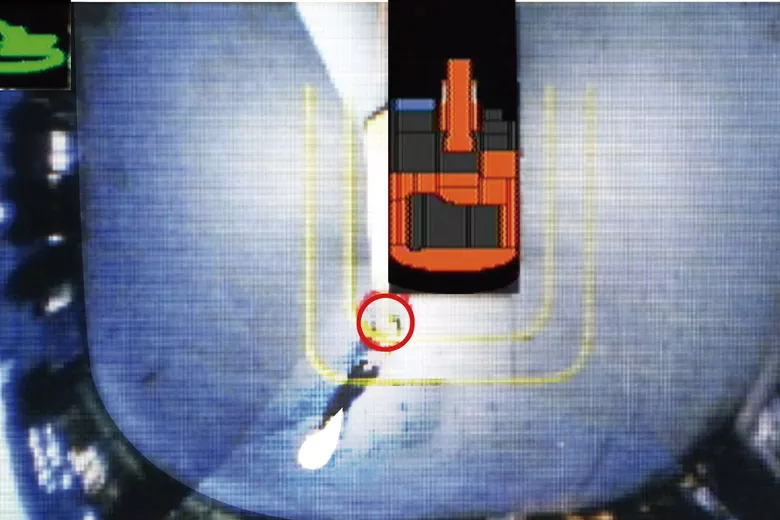

To further heighten on-site safety, all machines now come equipped with the Aerial Angle function as standard equipment. The operator can see what the area around the construction equipment looks like as if viewed from above, directly from the operator’s seat (photo).

Usually, the operator’s seat is on the left side of the excavator, with the arm on the right. As a result, the arm blocks the operator’s view of the right side of the machine, which can result in injury to someone approaching in the blind spot. Many cars now offer the same sort of aerial view to heighten safety when backing up or parking, offering a view of the entire periphery. Aerial Angle applies the same technology in construction machinery.

"Aerial Angle" allows the operator to check the bird's-eye view image centered on the machine on the monitor in the cab. It improves driving safety and contributes to reducing contact accidents.

Focusing on Mining Machinery

Not only North America, the Hitachi Construction Machinery Americas business also includes Latin America. While the major markets in North America are construction projects and civil engineering, onsite mining machinery, including mine development, accounts for the majority in Latin America.

“In Latin America, we have dealers in Brazil, Chile, Peru, Columbia, Suriname, and Mexico, plus one in the Dominican Republic, and another one in the Caribbean. Our goal for the time being is to boost our name recognition in those nations,” explains Babliton Cardoso, Senior Director of Mining Equipment Sales. Brazil-born Cardoso, who joined Hitachi Construction Machinery Americas in January 2022, has an extensive career in the mining and construction machinery industry including the European market and managing South American subsidiaries.

“In mining machinery it is crucial to maintain close relations with the customer. Dealers also have to offer a strong sales and service system, and we work with them to suggest new solutions to customers,” continues Cardoso. Mining machinery is not only huge, it has to be able to operate for long periods of time under severe conditions. Mines in Latin America are often located far from urban areas, making it difficult to secure workers, and in most cases mining machinery runs on a 24/7 schedule, 365 days a year.“A single piece of mining machinery is expected to run 6,000 – 8,000 hours a year (250 – 330 24-hour days), for ten years,” Cardoso explains. “On average there are six to eight rigid trucks to one mining excavator in a mine site, which means we have a chance to sell them as well. Today’s industry demands a whole range of systems and technologies to keep machinery working non-stop, so we have to work as a team with dealers to earn and keep customer trust.”

In recognition of the situation, Hitachi Construction Machinery will soon offer autonomous dump trucks to the Latin American mining industry, capable of driving themselves without human operators. “Safety is at the heart of all our technology,” says Cardoso. “Our mine operation management system helps prevent trucks from colliding with each other, while Aerial Angle and other onboard functions provide dump trucks with peripheral vision, just like our excavators. There are also functions to sense danger in the immediate vicinity when parking, and to brake to prevent collisions when traveling. Advanced stability control minimizes body slip, delivering stable performance even on South American mining roads in winter snow. These technologies are invaluable in selling our products to the mining industry.”

The sales strategy in the region is going to be built around excavators for mining. The high-performance, robust oil pump technology is crucial for giant excavators in the mining field.

Cardoso has confidence in Hitachi Construction Machinery: “We’re very strong in the field, because we can offer both excavators and dump trucks, backed up by the Hitachi Construction Machinery brand name and proven reliability. We’re further improving our rep in the mining markets we serve now, and are developing dealers in surrounding nations to offer mining machinery as well as unmatched dealer support. That’s basically the Hitachi Construction Machinery strategy for Latin America.”

Babliton Cardoso Sr.Director, Mining Equipment

The company is strengthening sales and services of mining products such as ultra-large hydraulic excavators and dump trucks for Latin America.

CEO interview / Independent operation in the Americas

Hitachi Construction Machinery faces a massive job in building and operating a business covering both the North and South American continents. We spoke with Al Quinn, CEO of Hitachi Construction Machinery Americas and the man leading the effort, about evolving their business, and what challenges they see in the future.

Al Quinn, CEO Hitachi Construction Machinery Americas

Rapid Growth for a Rapidly Changing Environment: Business Scale to Triple in Three Years

The company is extremely busy this year, but it’s worth the effort. Since Hitachi Construction Machinery Americas announced the termination of the agreement with Deere in August 2021, we have completely rebuilt our organization. The sudden expansion of the product line-up has driven major growth in the dealer network, with both existing and new partners. In rental equipment, we had to build new channels, while the parts business requires warehouses and distribution systems to handle the surging demand the expanded business will bring.

The types and sheer quantity of problems to be resolved are similar to those faced by a start-up, but we started with an enormous advantage: the strength of the Hitachi global brand in the Americas market. The power of the Hitachi brand name has been invaluable in Hitachi Construction Machinery Americas’ organizational revamping, too: the number of employees jumped from 40 last year to 140. Even discounting the people transferred from Hitachi Construction Machinery in Japan there were still 100 local hires, and we got more than 5000 applications when we posted the help wanted ads.

The labor situation in the US is extremely tight right now, making it difficult to attract quality people, and we were astonished to be swamped: everyone saw us committing to a massive expansion and wanted to be part of it. The Hitachi Construction Machinery brand is clearly respected in the Americas market. The product line-up is also highly competitive, and prospective buyers are especially interested in Hitachi Construction Machinery brand excavator technologies that were not available through Deere. The dealers selling our construction machinery also handle products from other manufacturers and have considerable knowledge and experience in the industry, but one major dealer phoned me one day and said they had never seen such a reliable machine with just the right mix of technology before and wanted to place an order. It’s just more proof of our ability to provide the market the best machine possible.

Upgrading the Parts Distribution, Maintenance Support Systems

One major challenge we’re dealing with right now is the parts business. When Hitachi Construction Machinery Americas launched an independent operation in March 2022, with the introduction of mining equipment and excavators, our parts volume increased more than tenfold. We have one parts warehouse in Jackson, Georgia, but we need another one, so we’re urgently building a system for parts storage and distribution together with Vantec Hitachi Transport System (USA), Inc., an American subsidiary of Hitachi Group member Vantec HTS Forwarding, Ltd.

We need a bigger, better system because demand for construction machinery in the US is surging. Inventory levels at construction machinery dealers and rental businesses are very low, and everyone is hunting for a way to get more machines. The same situation exists in Latin America, where demand is growing fast for large construction machinery, especially in mining. Global supply can’t keep up with demand.

The business environment is changing at an incredible speed. If we can successfully capture this demand, our operation will triple in the next three years. We have to get a lot of things done for that to happen, though: expand our dealer network, upgrade our technical and maintenance support stance, boost the quantity of products and parts we ship, and get our whole supply chain in order. Lucky for us, dealers and customers are eager to work with us. They welcome Hitachi Construction Machinery's commitment to the Americas market and want to grow with it. I’m going to do everything in my power to make the most of this phenomenal opportunity.